Your Dehumidification Experts

Welcome to the HVAC and Environmental Systems division of ITG. We provide air treatment for critical applications as an engineering based manufacturers’ representative firm. We are active in residential, commercial, institutional, and industrial businesses. Our focus is to provide reliable and innovative products resulting in high-efficiency systems for specialty applications with the goal towards LEED (Leadership in Energy and Environmental Design) with Green Building designs.

ITG’s HVAC and Environmental Systems Division is acknowledged as a leading manufacturers’ representative, specializing in LEED/Green building designs, and unique and critical applications. Our concentrations is in providing:

- energy-saving heating/cooling systems,

- energy recovery to reduce operating cost,

- indoor air quality to improve people’s productivity and health,

- humidity control for comfort and building protection, and

- specialty built systems for custom applications

We have over 25 years of engineering and application experience. We are also strongly supported by the manufacturers we represent with their industry credibility and quality products. We pride ourselves on bringing “leading-edge” technology to building owners.

Our Application Engineers serve the engineering, contracting, and building owner community throughout Maryland, Washington DC, Northern Virginia, and Southern Delaware counties.

We are an adaptive partner that assists consulting engineers, mechanical contractors, and building owners in designing HVAC and Environmental Systems. We provide efficient and cost-effective indoor environmental solutions. In order to meet the specific demands of your project, we capitalize on our strong relationship with our equipment manufacturers. We offer the highest quality equipment and professional expertise to achieve the desired building environment control.

Our team of sales engineers has an intimate knowledge of each product design and its application. This combination of quality products, training, and experience is instrumental in the success of your building’s indoor environment control system.

As an added value to our customer, we have aligned ourselves with local technicians to provide service on our equipment. Qualified technicians are evaluated through a rigorous interview process to determine their strengths and are then matched to an appropriate manufacturer for product training.

Our qualification and training process ensures our customers have access to factory-authorized service for their specialized/custom equipment.

Our trained staff are ready to coordinate warranty claims and parts orders. We will work with you and our manufacturers to obtain the parts and service your project needs. Upon request, we can coordinate a certified factory-authorized technician for service and maintenance contracts.

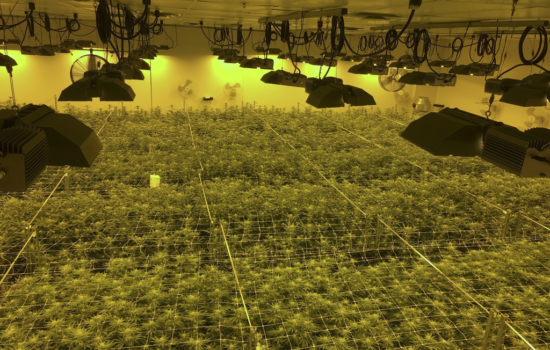

Anden manufacturers dehumidifiers and steam dehumidifiers for the indoor farming application. The equipment is plug and play equipment with built in digital control and optional remote controls with a 5 year warranty.

Anden dehumidifiers put you in control of your growth environment. You get maximum moisture removal and VPD control, with on-board and remote monitoring capabilities to make it all intuitive. Simply put, these grow-optimized products are designed with your plants in mind. Dehumidifiers range from 70 pints per day to 710 pints per day. The equipment can be suspended, freestanding or ducted to meet different needs.

Anden steam humidifiers put you in control of your grow environment. You get maximum moisture, VPD, and on-board control, and remote monitoring capabilities to make it all intuitive. Simply put, these grow-optimized products are designed with your plants in mind.

Desert Aire Corp. is a manufacturer of customized refrigeration-based industrial dehumidifiers

that provide effective, efficient solutions to all of your humidity problems. A Desert Aire system

properly neutralizes humidity to promote greater comfort, structural integrity, improved indoor

air quality (IAQ) and higher energy savings. Their IAQ units also meet ASHRAE Standards 62 and 90.1. As the authority in dehumidification, Desert Aire can design a solution for almost any application including:

- Poolrooms

- Natatoriums

- Water Parks

- Water and Waste Treatment Plants

- Grow Rooms

- Ice Rinks

- Warehouses

- Libraries

- Fitness Center & Recreation Centers

- Outside Air Treatment

NanoSox is a 3rd generation fabric that is more improved over its competitors in the fabric air dispersion market. They provide a fabric air dispersion system has many distinctive features, such as even airflow with great comfort, aesthetic, fire inherent and or resistant, condensation free, hygienic & healthy, quick installation, easy cleaning and maintenance, etc. There are multiple fabric duct systems feature dispersion options, differentiated by the size and used to regulate the airflow in a fabric duct system. Multiple colors are available to blend well with any indoor decoration with both stock and custom color/design.

NanoSox provides specialized cable and track suspension system bring you quick installation and reduce material waste on the job site. Installation time is substantially shortened, accounting only 1/10 or less of that of metal duct system. NanoSox has a wide variety of applications especially in in places with large and high space and without a ceiling including:

- Supermarkets

- Commercial Buildings

- Exhibition Centers

- Cinema

- Manufacturing Facilities

- Indoor Farming

- Indoor Pools

NovelAire Technologies has been supplying customers with products that efficiently supply fresh air and independently control humidity in home or work environments for over 25 years. They offer commercial, residential and special purpose desiccant dehumidifiers: building humidity control, 100% outdoor air, ice rings, cold storage as well as other applications with a low temperature and humidity requirements.

NovelAire EC wheels are AHRI certified, a Energy Star Partner and a member of the U.S. Green Building Council.

NovelAire Technologies systems have a variety of applications including:

- Ice Rinks / Cold Storage Units

- Storage rooms and vaults

- Water treatment facilities

- Manufacturing facilities

- Outside air units

- Recirculation units

Manufacturer of Finned Tube Heat Exchangers Since 1928

Super Radiator Coils has been engineering and building cost effective, durable and thermal

efficient heating coils and cooling coils, to meet each customers challenging and unique heat

transfer project. Super Radiator Coils customers benefit from a wide range of coil products and heat transfer solutions. Here are a few products we offer:

- Heating Coils

- Cooling Coils

- Refrigerant Coils

- Heat Recovery Coils

- Vapor Recovery Coils

- HVAC Coils

- Air Conditioning Coils

- DX Coils

- Ammonia Coils

- Hot Water Coils

- Chilled Water Coils

- Steam Coils

- Steam Distributing Coils

- Evaporator Coils

- Condenser Coils

Need your coil field measured, call us today and schedule a “Free” site coil measurement service.

Learn more about what Super Radiator Coil does and how they can building your coil!

Presentations

Ice Rinks

The speaker will discuss when, where and how to use refrigeration based dehumidification equipment in an ice rink facility. Cover different types of ice rink dehumidification systems and the proper way to address the outside air requirements. Review Ice Rink Design and what issue should be addressed with the architect.

Psychometrics

The speaker will review the psychometric chart, terms, use, and formulas used to calculate various loads. We will discuss the refrigeration process used in a mechanical air conditioner and a dehumidifier. In addition, we will look at key design features of the major components. We then explore how a refrigerant type dehumidifier recovers the heat from the water vapor and disperses the energy to different heat sinks to optimize recover energy. Psychrometrics will be used to ad in describing all processes of the refrigeration circuit and its impact on air.

The speaker will discuss dehumidification basics with a focus on psychometrics, moisture loads, refrigeration dehumidifaction technology, and the impact of ARI Standard 910 and 920. First, psychometrics basics will be reviewed with a focus on determining moisture loads. Using the psychometric chart and local weather data, we will explore the influence of ASHRAE weather data, bin data, and joint frequency plots used in determining outside air loads. In addition, we will briefly review other moisture load sources used in selecting the appropriate dehumidifier. Next, refrigerant dehumidification technology will be discussed and compared against a conventional DX system. We will look at the similarities and differences between the following basic DX dehumidifiers: an industrial unit, a low temperature unit, a pool unit, and an outside air unit. While discussing the different dehumidifiers, we will apply various applications and see how a dehumidifier can be implemented to handle the outside air dehumidification requirements plus the majority of the space latent and sensible loads. Each dehumidifier operation will be discussed with the aid of a psychometric chart. Lastly, we will discuss the impact of ARI Standard 910 and 920 when selecting a dehumidification system.

Outside Air Treatment

The speaker will discuss when, where and how to use refrigeration based dehumidification equipment Explore why standard A/C systems have problems and fail with 15% or more outside air. Cover different types of refrigeration based dehumidifiers, fix hot gas reheat, variable hot gas reheat and liquid sub-cooled reheat in parallel and series system designs. Will investigate 100% outside air, single-pass, unit designs with various technologies such as DX, heat plates, and heat pipes. Will investigate the impact of exhaust air energy recovery systems and how an enthalpy wheel can compliment a dehumidification system. Review the various control strategies to control outside air system with respect to both compressor operation and leaving air temperature control. Discuss various applications to explore how a dehumidifier can be implemented to handle the outside air dehumidification requirements plus majority of the space latent and sensible load.

The speaker will discuss parallel HVAC design with a DX-DOAS integration and its control strategy to achieve the lowest building capital and operating cost. A DOAS can reduce the supply air to eliminate all outside air moisture plus be dry enough to absorb the building’s internal moisture loads. Incorporating a DX-DOAS system within a parallel HVAC design allows the engineer to provide the by-products of the DOAS: free heating and cooling. DX-DOAS compressor control strategies will be explored. The question, “When is a compressor(s) energized and/or staged to minimize operation cost while still controlling humidity?” will be addressed. When utilizing the DX-DOAS by-products, the system must include a leaving air temperature control strategy allowing the offset of building loads with the free by-products while preventing overheating and sub cooling of the building’s spaces. In addition, a discussion on night setback and CO2 control strategies will be presented. Night setback will discuss an energy saving mode with unoccupied building humidity controlled. Plus, we will explore a simplified CO2 control strategy for demand control ventilation.

The speaker will discuss the refrigeration circuit and components, how they work and their importance for year round successful and efficient operation. How to apply 100% Outside Water Source Heat Pump equipment and control it in dehumidification, cooling and heating mode. Look at different control and installation options to minimize capital and or operating cost for the entire project. Discuss the unit’s sequence of operation using a psychometric chart. Look at advantaged and disadvantaged of the Reverse Cycle Heat Pump on Recirculation and or Mixed Outside Air and in 100% Outside Air Applications. Compare a Reverse Cycle Heat Pump to a New 2002 Technology Dual Evaporator Water Source Heat Pump. Explore new energy management techniques that reduce utility cost and capital cost by properly designing with a Dual Evaporator System for 100% Dedicated Outside Air Systems.

Poolrooms

The speaker will discuss poolroom construction, do’s and don’ts and how to protect the structure from corrosion due to condensation. Review what types of concerns and questions that should address when speaking with the owner, pool operator, architect, chemical provider, electrical designer and contractors. Discuss pool water and air relationship. Look at basic dehumidification. Discuss 6-Key Goals in Pool Room Design of the Building Envelope.

The speaker will discuss when, where and how to use refrigeration based equipment. Covering types of refrigeration based natatorium dehumidifiers, standard basic systems, economizer systems, purge systems, heat pipe systems, and Desert Aire Select Aire Systems. Review an energy analysis and comparison of all types of dehumidification systems.

The speaker will explain how Desert Aire has been a leader in the field of dehumidification of natatoriums with a unique energy recovery sequence to capture the energy of the exhaust air and use it in returning the energy back to the pool facility. This system can offer the lowest cost of operation while protecting the building from moisture damage. A new design opportunity has been developed for this industry using a unique source capture duct design to remove the damaging effects of chemical build-up that occurs in a natatorium under heavy use. Desert Aire has enhanced its sequence of operation to interface and control the source capture technique while also maintaining the building’s negative pressure. This new sequence combines unique sensors to activate higher levels of exhaust and corresponding ventilation air to eliminate the chemical build-up while still maintain the highest level of energy recovery.